There has long been a debate over whether aluminium or steel is the better choice for scaffold tubing. Some contractors will always prefer one over the other, but for some it depends on the type of job they’re working on.

So what are the benefits of using aluminium tubing over steel?

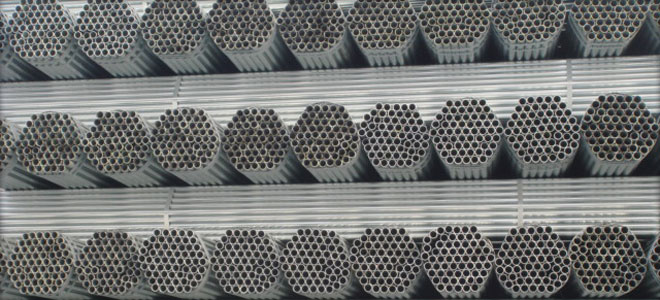

Scaffold tubing, such as those available from if sections of metal pipes that are used to build a scaffolding tower. They’re connected together via a series of couplers to create walkways and different levels alongside a building or other structure. Whether the tubing is made from aluminium or steel, it can be easily cut to size.

The benefit of constructing scaffolding in this manner is that the modular system allows any shape or size of scaffolding to be built, depending on the requirements of the job. There are times when aluminium or steel tubing is the best option. However, what makes aluminium, in particular, ideal for use on scaffold tubing?

Easy to Transport

The major benefit of aluminium over steel is that it’s extremely lightweight. This makes the tubing easy for workers to carry on and off vehicles. This lightness allows the scaffolding to be constructed quicker, as the tubing can be lifted easier, so they can work faster. This means that you can start work on the project earlier and waste less time and money setting up.

Heavy Loads

A lightweight material that’s also able to carry heavy loads is extremely useful. This is why aluminium tubing is so popular. Once the scaffolding is constructed, it can carry heavy loads, suitable for most construction site applications.

Extremely Durable

Scaffolding is erected and then remains in place until the job is finished, regardless of the weather conditions. Therefore, it’s important that the metal you use is durable in order to stand up to the temperature extremes and rain.

Aluminium is resistant to rust and corrosion, making it perfect for long periods of time outdoors. If you choose to use steel instead, it must be galvanized or treated to make it weatherproof. On the other hand, aluminium needs very little maintenance and will still be safe to use if it’s kept outside.

Keeping Costs Down

The economic downturn has made all businesses look again at their outgoing costs and see where they can make savings. Within the construction industry, swapping to aluminium pipes will make a job more cost effective, due to their lightweight properties and durability.

However you choose to construct your scaffolding, the quality of the products is most important. Using sub-standard tubing could put the lives of your workers in danger. The tower should always be built in the correct manner, with properly connected joints.

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

Thank you, your article surprised me, there is such an excellent point of view. Thank you for sharing, I learned a lot.